DFT Electro-hydraulic servo dynamic testing system

Description

DFT series Electro-hydraulic servo dynamic testing system consists of frame, pump station, servo control system, computer and software, accessories and pipeline system. It can be applied to dynamic fatigue and static performance test of various materials, structural parts and components.

Application

1、Part vibration and impact test.

Description

DFT series Electro-hydraulic servo dynamic testing system consists of frame, pump station, servo control system, computer and software, accessories and pipeline system. It can be applied to dynamic fatigue and static performance test of various materials, structural parts and components.

Application

1、Part vibration and impact test.

2、Dynamic high cycle fatigue test and low cycle fatigue test.

3、Safety evaluation and working condition simulation of actual specimens.

4、Conventional mechanical property test and fracture force test under the control of static constant rate, constant strain and constant stress.

5、Fatigue life, crack growth, fracture toughness performance test for material or components.

6、It is applicable to quality control and experimental research in the fields of aerospace, aviation, vehicles, building components, rail transit, atomic energy and ship.

Features

1、Frame structure: Dual columns (Below 300KN) and four columns (Above 300KN).

2、Crosshead: hydraulic tightening, hydraulic lifting and descending. Flexible adjustment of test space.

3、Actuator is designed to integrated with frame. It can be placed top or bottom.

4、The actuator has a built-in LVDT displacement sensor and external Load sensor Electro-hydraulic servo valve.

5、Actuator amplitude limit position is equipped with hydraulic buffer, avoiding the damage out of control.

6、Various grips and accessories supply: Hydraulic clamping chuck, threaded chuck, Three-Point Bending accessories, Four-Point Bending accessories etc. We can customize grips and accessories according to requirement.

7、Various specification Constant pressure servo pump station for selection. Range: 15-1500L/min.

8、Control system: Digital Control Electro-hydraulic Servo Control system.

9、Software: Provide dynamic and static software for selection.

10、Environment test equipment is optional: such as high temperature furnace and low temperature chamber.

11、External oil cooling circulation device is optional.

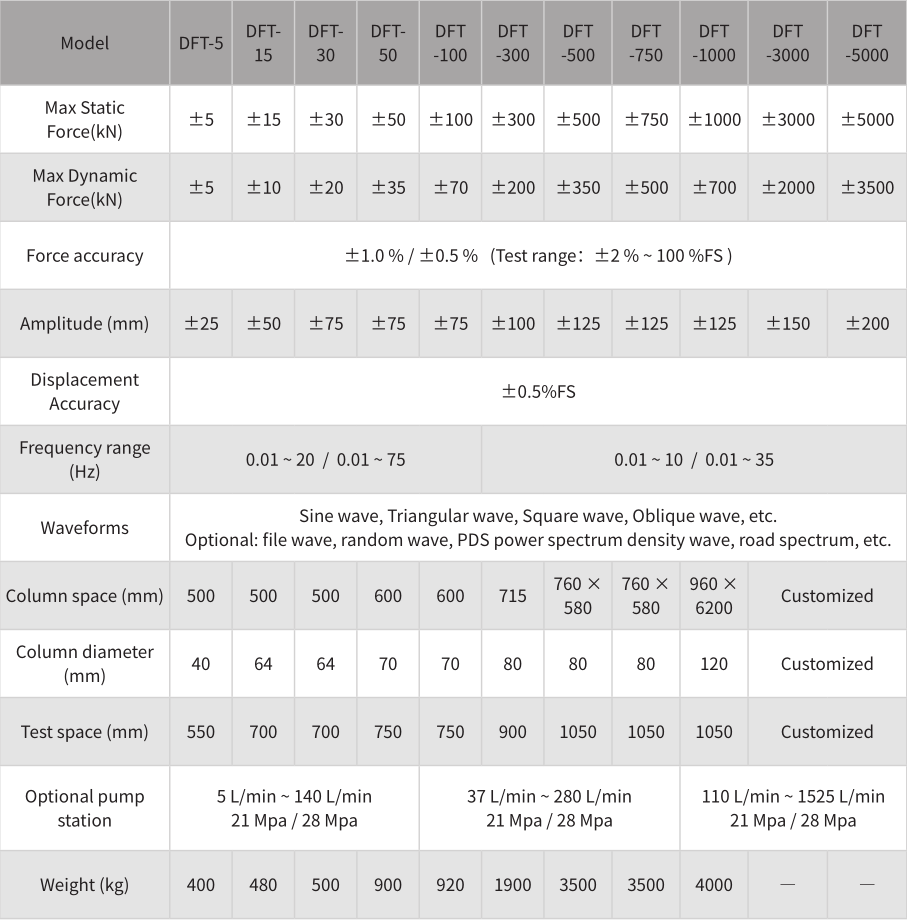

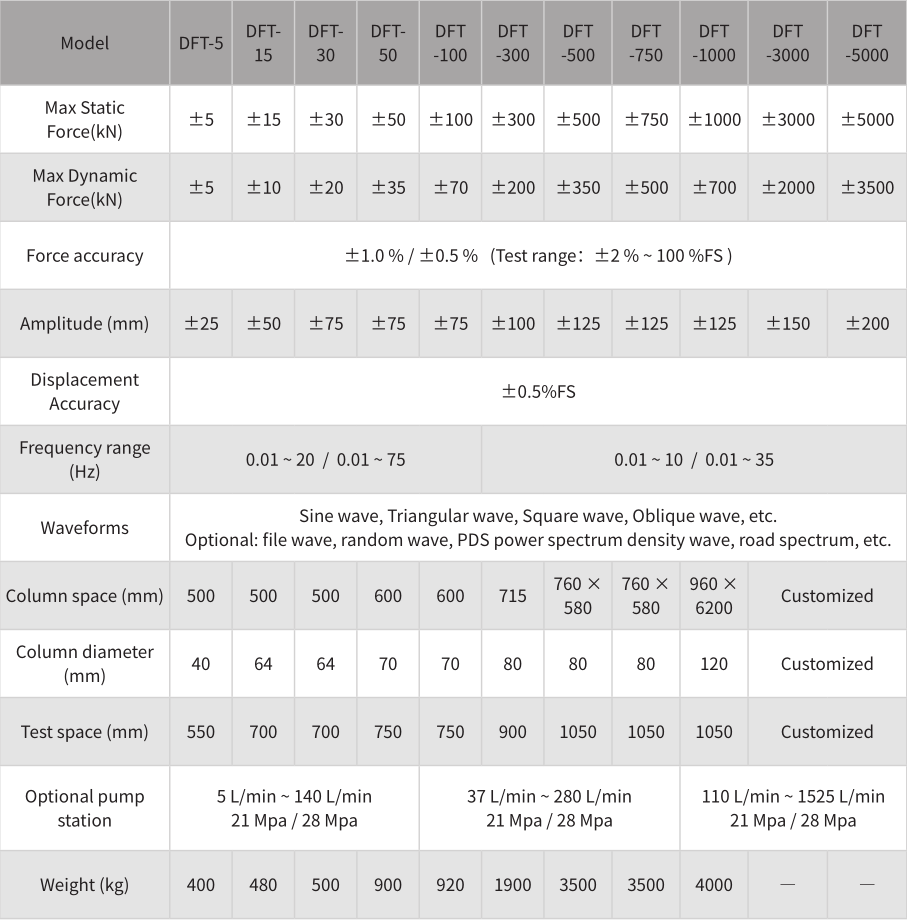

Specifications